GM Truck Clutch Installation Best Practices: How Proper Hardware Improves Performance and Reliability

How Proper Hardware Improves Performance and Reliability

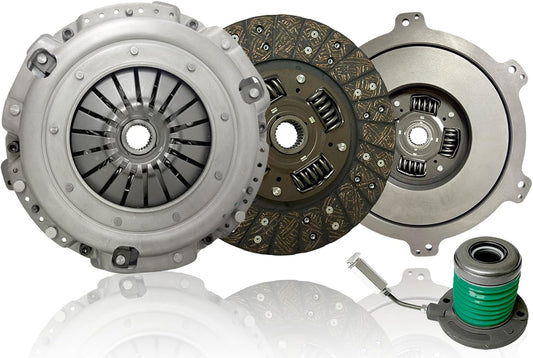

When it comes to GM truck clutch performance, quality components are only part of the equation. Proper installation techniques and correct hardware selection play a critical role in achieving smooth operation, long service life, and reliable clutch release—especially in 12” GM truck clutch applications.

Many clutch-related concerns are not caused by defective parts, but by small installation details that can easily be overlooked. By following proven best practices, technicians and installers can maximize the performance of any automotive clutch system and help prevent premature wear.

Why Hardware Choice Matters in GM Truck Clutch Systems

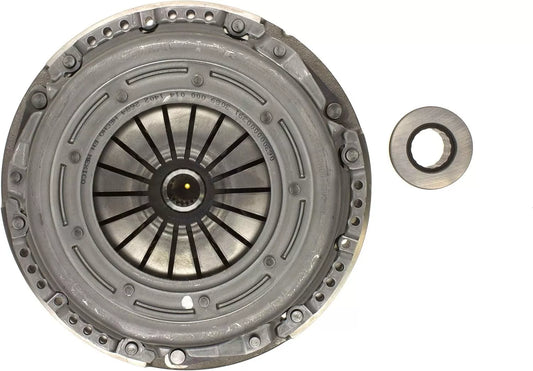

In GM truck clutch installations, using the correct fasteners is essential. For certain applications—specifically clutch kits 04-064 and 04-087—hardware selection plays an even more important role in ensuring proper clutch operation.

Using over-sized lock washers on the clutch mounting bolts in GM trucks equipped with 12” clutches can interfere with normal clutch movement. Due to their larger diameter, these washers may extend into the clutch cutouts and contact the clutch disc, affecting smooth release and engagement.

That’s why professional installers recommend the following best practices:

-

✔ Standard 3/8” diameter washers, designed to fit correctly without interfering with clutch components

-

✔ High-quality thread locking compound as an alternative to over-sized washers

-

✔ Always torque bolts to manufacturer specifications

These steps help maintain proper alignment between the clutch disc, pressure plate, and flywheel—supporting consistent engagement and smooth clutch release.

Preventing Interference and Ensuring Smooth Clutch Release

A properly installed 12” GM truck clutch allows all components to move freely as designed. Correct washer size and proper torque prevent unnecessary contact with clutch cutouts, reducing the risk of drag, chatter, or inconsistent release.

This attention to detail supports:

-

Improved clutch release performance

-

Reduced wear on clutch discs and pressure plates

-

Longer overall clutch lifespan

-

Better drivability under load and towing conditions

Professional Installation Makes the Difference

Experienced technicians understand that clutch performance depends on precision. From hardware selection to torque values, every step matters. Following OEM-recommended practices helps ensure that the clutch operates reliably in both daily driving and heavy-duty applications common to GM trucks.

Pairing proper installation methods with a high-quality performance clutch results in a system that drivers can trust mile after mile.

Southeast Clutch: Engineered for Quality, Trusted for Performance

At Southeast Clutch, our products are designed with durability, precision, and real-world performance in mind. Each GM truck clutch is engineered to meet demanding conditions, delivering consistent engagement and dependable power transfer.

When installed using best practices—correct hardware, proper torque, and attention to detail—Southeast Clutch products help technicians and drivers achieve maximum reliability and confidence on the road.