CLUTCH INSTALLATION GUIDELINES

Clutch Installation Guide

- Evaluate the Cause of Previous Failure: Carefully assess why the last clutch failed to ensure contributing factors are resolved before installing the new clutch.

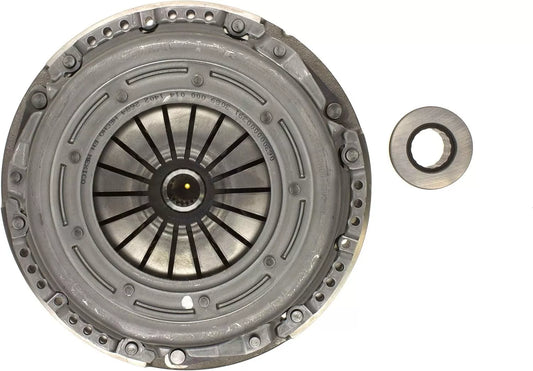

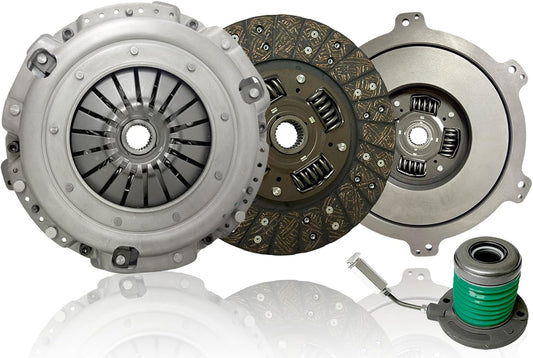

- Flywheel Preparation: The flywheel must be replaced or machined according to the specifications indicated on the supplied Flywheel Step card. Inspect dowel pins (if applicable) to make sure they are straight and smooth. It’s recommended to pre-fit the clutch cover over the dowel pins before final installation.

- Pre-Inspection: Inspect the clutch for any shipping damage. Clean and degrease the bell housing, removing all dust and debris. Take notes or photos of drivetrain components prior to disassembly to ensure correct re-installation.

- Test Fit the Disc: Slide the disc onto the input shaft to confirm it moves freely. If it doesn’t, clean the shaft splines and file any burrs from the disc. DO NOT FORCE THE DISC ONTO THE SHAFT. Contact us if fitment issues occur.

- Lubrication: Lightly grease the input shaft splines using high-temperature grease or dry graphite lubricant. Insufficient lubrication may cause disengagement issues.

- Inspect Clutch Release Fork & Pivot: Check for cracks or wear. It is highly recommended to replace these components if they show any signs of wear.

- Inspect Release Bearing Quill/Retainer: Check for wear. If there is wear, it is recommended to replace it. Lubricate the new release bearing collar and apply a light coat of grease to the outside of the quill/retainer tube.

- Assemble Clutch: Assemble the clutch cover and disc, ensuring the disc faces the correct direction (“Flywheel Side” or “Pressure Plate Side” label). Use the alignment tool and bolt the assembly to the flywheel, aligning with the dowel pins. Tighten bolts in a diagonal pattern. NEVER use air (impact) tools to install a clutch cover assembly.

- Refit Gearbox: Use a proper jack or support apparatus. Do not force the input shaft into the disc as this can bend the disc and cause disengagement failure.

- Clutch Adjustments: Adjust per vehicle manufacturer specs. Inspect clutch cables and/or hydraulic lines for leaks or damage. It may be necessary to reset the clutch master cylinder push rod for ideal pedal engagement.

- Break-In Period: Drive normally for the first 500 miles to allow the clutch to break in properly. Note: High-performance clutches use friction materials that may cause slight shudder or drivability compromise during break-in.